MFA graduate uses 3D printing to contribute to local hospital’s COVID-19 care

April 14, 2020 : By Ryan Klinker - Liberty University News Service

After being educated in 3D technology through Liberty University’s Master of Fine Arts (MFA) in Graphic Design program, Keenan Sultanik (’19) is using a self-built 3D printer to create items needed by his local hospital in California to continue treating those affected by the COVID-19 pandemic.

After founding the Creative Arts department at West Coast Baptist College in Lancaster, Calif., Sultanik came to Liberty to obtain his master’s in order to meet his new position’s academic credentials, and an elective course in 3D graphics sparked an interest in the subject that he did not expect.

“The reason I took the 3D class was because I wanted to dive into it more and I knew it would push me, and it helped me develop skills I needed for manipulating 3D models and thinking in 3D,” Sultanik said. “It took something I had dabbled in but didn’t have practical skills in, and it gave me the skills, knowledge, and motivation to go further into this.”

Inspired to dive deeper into the creativity of the art form, Sultanik ordered the supplies to build a Delta 3D printer and assembled it over the course of a weekend. Before taking the course, his skill set was mainly a practical understanding of branding, photography, and graphics, but he said that the program took his interests and understanding to the next level.

“It pushed me in areas I wouldn’t have gone into otherwise, like illustration or 3-D graphics, and it helped me develop as a creative person,” Sultanik said. “I don’t think I would have ever taken the time to build a 3D printer in the first place if I didn’t think I’d have an outlet or the knowledge base to be able to use it in the future.”

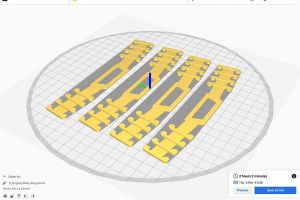

When the swell of COVID-19 began to occur, Antelope Valley Hospital in Lancaster, Calif., reached out to their community to ask those who had a 3D printer to create a small but useful strap for surgical masks, which keeps the masks securely on the face to guard against contamination.

A digital model of the items Sultanik is making for his local hospital

“From what I know, the masks are sort of a one-size-fits-all item, but for some people they don’t always fit tightly, and if there’s a gap they can be exposed when dealing with patients,” Sultanik said. “These parts I’m printing go around the back of the head and allow them to loop through the strap to more comfortably and effectively hold the mask in place, instead of looping it around their ears.”

“Our local hospital said they have 200 medical staff just in their ER department and they need one of these (straps) for every single person on their entire staff,” he said.

After hearing from a friend working in the hospital about a shortage of masks for hospital staff who are not directly in the patient care field, Sultanik has also used a design from Rowan University to make 3D printable masks to donate.

Looking back at his time studying with Liberty and this newfound opportunity to serve his local community in the COVID-19 crisis, Sultanik sees his 3D printing project as something that God has had a hand on since he studied the craft on Liberty’s campus two years ago.

“I don’t want to take all the credit for what I’m doing because God knew that the hospital was going to need this two years ago when I took that class as an elective,” he said. “He orchestrated all of that so that I could use what I’d learned at Liberty to be a blessing to somebody else, and it’s exciting to be a part of that.”