Search News Archives

Filter News Articles

Additional Navigation

Engineering students collaborate with industries on capstone projects

May 8, 2024 : By Ted Allen - Office of Communications & Public Engagement

Capstone, also known as senior design, is the culminating academic experience for Liberty University School of Engineering (LUSE) students and a significant résumé-enriching achievement as they prepare to transition to professional careers.

“Each student works on a team of four to six to design a new product or process or make significant design improvement on existing systems,” said Dr. Howie Fang, a professor and chair of the mechanical engineering department and director of LUSE’s capstone program. “It’s a creative activity, and students do that for their client, who works with the student team over the period of two semesters.”

That creativity and collaboration was on display during Thursday’s Engineering Capstone Expo in the Montview Alumni Ballroom. For this academic year, LUSE offered 22 capstone projects to 97 engineering students with 18 projects from industry partners. Area businesses included Automated Conveyer Systems Inc., Centra, Delta Star, Framatome, Harco Fittings, Lawrence Companies, and Master Engineers & Designers. Students also worked with multi-industry companies such as Textron, and government agencies like NAVAIR, who have provided funding for and benefited from students’ innovative capstone projects. (See the full list of industry sponsors below.)

“It is very important for our students to learn real-world engineering problems and how to find solutions to those problems before they go out and get into industry as engineers,” Fang said. “Then, they are prepared and comfortable applying what they have learned in the classroom to real-life engineering challenges in their new jobs.”

Capstone teams involved students from all five engineering programs: mechanical, electrical, computer, industrial & systems, and civil engineering.

“Dr. Howie Fang is a world-leader in design optimization methodologies and has taught that in the context of the Creationeering process to the senior students while integrating it with real-world engineering problems,” School of Engineering Dean Mark Horstemeyer said, with Creationeering referring to his coined term for the interface between business and engineering and the creative inspiration from God in students’ research and design. “I am so proud to have Howie Fang in the LUSE as his leadership has raised the standard for the school.”

A successful capstone project that incorporates partnership and funding from industry can give graduates the edge they need in interviews to land positions and launch their careers with some of the top engineering companies in the nation.

A successful capstone project that incorporates partnership and funding from industry can give graduates the edge they need in interviews to land positions and launch their careers with some of the top engineering companies in the nation.

Such was the case for Tanner Randall, who will start this month at Framatome in its thermal hydraulics and component testing center after leading a team of six mechanical engineering students who worked under the supervision of Framatome mechanical engineer and software developer Greg Troyer to analyze the natural frequencies of nuclear reactor vessel internals (RVI), which facilitate fission in extreme environments. Christopher Pace, an electrical engineering student who worked on another Framatome-sponsored project, has also been hired by the company, which has its North American headquarters in Lynchburg, Va.

Katherine Rioux and fellow mechanical engineering students Fady Fayek, Caleb Schaible, and Logan Drawbaugh worked with Dr. Andy McIntosh from Leeds University in England to develop a Biomimic Novel Spray System, using the bombardier beetle as its model for extinguishing fires. She has landed a job working on E2D Hawkeye Airborne Command and Control Aircraft at NAVAIR in Patuxent, Md.

“It’s been a steep learning curve, but the cool thing about being tossed into the deep end is you either sink or swim, and I didn’t want to sink, so I learned,” said Rioux, who had internships with NAVAIR over the past two summers.

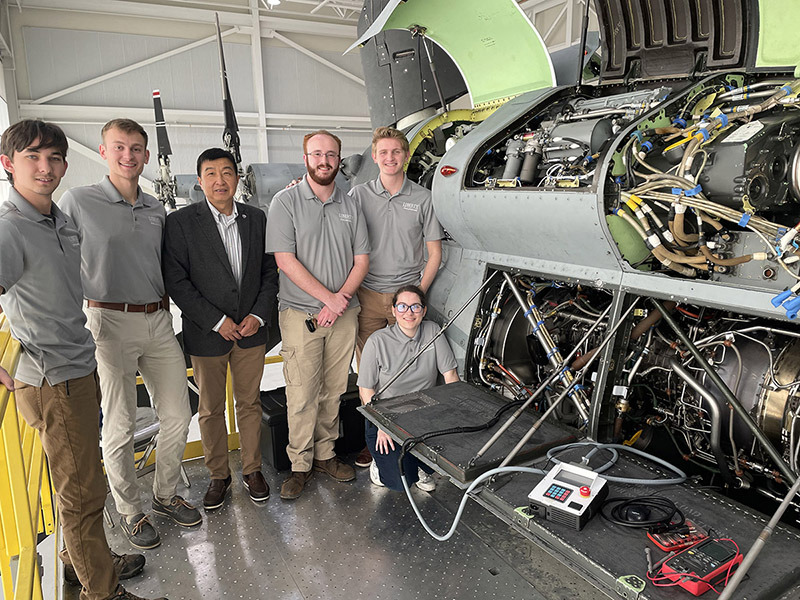

At last spring’s Expo, Josh Ingram and his team won the Capstone Legacy Award for their best product design for NAVAIR, a small tool that can be used to repair the engine of the V-22 Osprey tiltrotor aircraft. Ingram was hired by BWXT last May while Zach Deluth, another member of this team, was hired by NAVAIR.

“The team worked with NAVAIR really well, and the product the students delivered to them is ready to be made for them to use to maintain these aircraft, so they were really happy,” Fang said.

Due to the quality of work produced by the engineering students on that capstone project, NAVAIR’s Cherry Point, N.C., location sponsored two capstone projects for Liberty’s engineering students this year.

Several of the seniors said the capstone projects stretched them more than any other class they had taken toward their degree, challenging them to put what they have learned in the classroom into practical application.

“It’s hands-on, working with a real customer, solving real problems, and it really made them think through, identifying what the problem is, coming up with solutions to that problem,” School of Engineering Lab Manager Marc Jantomaso said. “They built really good relationships with the clients.”

In recent years, as the School of Engineering has grown — both in number of students and faculty and in reputation in the Lynchburg, Va., area and around the nation and the world — more and more connections have been made between graduating seniors and area engineering companies.

“Through the capstone program, we have built up some very good relationships with industry that will tremendously benefit our engineering students, as well as the industry, providing the students with opportunities to refine their learning and open doors for employers to hire highly skilled graduates,” Fang said. “It’s a win-win situation. We can have more impact for students if we bring real-world applications, real-world projects from industry and let students work with industry people directly in these projects.”

This year, the projects received more than four times the total amount of funding as last year, allowing the seniors to develop more elaborate projects with greater functionality.

“They have more financial resources now, so they can do more,” Fang said. “When you go out to industry, your project can run anywhere from hundreds to thousands of dollars. That is the scale type of work from industry, and that is very beneficial to students if you can have a project with that complexity. So, from that perspective, we try to attract as many industry projects as possible.”

With genius inspired by God, and plenty of direction from faculty advisors and the clients they are doing their capstone projects for, the student teams “make miracles happen,” said Liberty President Dondi Costin, who attended the Expo.

“I was blown away at every single station, and I couldn’t believe it,” he said. “This is a true testament of your education … (and) exactly what Liberty University is all about. It’s taking young men and women who have natural talent and who have been raised with character and who are brought here by God, who have an individual ability and skill and passion and motivation and coming together as a team and using that skill in concert with the skills of others who are just as intelligent and passionate and gifted.”

2023-24 Engineering Capstone Industry Sponsors

Automated Conveyer Systems (ACS) Inc.

Centra Health

Corvid Technologies LLC

Delta Star, Inc.

Energy & Automation, Inc.

FarmBot Inc.

Framatome

Harco Fittings

Kapstone Projects LLC

Lawrence Companies

Master Engineers & Designers

McKee Foods Corporation

U.S. Navy’s Fleet Readiness Center East (NAVAIR)

Textron Specialized Vehicles